RSR Fellowship - CDER

A complete application consists of:

- An application

- Transcripts – Click here for detailed information about acceptable transcripts

- A current resume/CV, including academic history, employment history, relevant experiences, and publication list

- Two educational or professional references

All documents must be in English or include an official English translation.

If you have questions, send an email to FDArpp@orau.org. Please include the reference code for this opportunity in your email.

Oral disintegrating films (ODF) provide rapid therapeutic effect and high patient compliance with pediatric and geriatric patients especially those suffering from neurological diseases. The manufacture of ODF products involves solvent casting of a liquid mixture containing film former, plasticizer, anti-adherent, sweetener, color and flavor onto a polyester film. Thus minor changes in critical product and process variables (e.g., drying rate and temperature) might result in film forming and result in product quality failures over the shelf life. . Variation in plasticizer concentration over the film may result in alternation of their critical quality attributes (CQA) such as tensile strength, elongation at break and stickiness. All of these product failure modes severely impact the ODF product quality, leading to recalls that may result in drug shortages and have impact on public health. it is proposed to use a Quality by Design (QbD) approach for studying the effect of products and process variables on the quality of ODF product using lamotrigine as a model drug. The outcome is expected to be beneficial to the FDA scientists involved in the review of NDA and ANDA submissions relevant to ODF.

Objectives are to use a Quality by Design (QbD) approach for studying the effect of products and process variables on the quality of ODF product using lamotrigine as a model drug. The formulated lamotrigine ODF will be characterized for thickness, Dynamic vapor sorption (% of moisture uptake, % of moisture content), mechanical properties (Tensile strength, %elongation at break, Young’s modulus, folding endurance), wettability and water vapor transmission rate. The films will be also tested for drug assay, disintegration and dissolution as per the USP procedures. The uniformity of drug distribution and thickness during the preparation will be monitored by Via-Spec II Hyperspectral Imaging system equipped with VNIR and SWIR spectral cameras.

This program, administered by ORAU through its contract with the U.S. Department of Energy to manage the Oak Ridge Institute for Science and Education, was established through an interagency agreement between DOE and FDA. The initial appointment is for six months, but may be renewed upon the recommendation of FDA and contingent on the availability of funding. The participant will receive a monthly stipend commensurate with educational level and experience. Proof of health insurance is required for participation in this program. The appointment is full-time at FDA in the Silver Spring, Maryland, area. Participants do not become employees of FDA or the program administrator, and there are no fringe benefits paid. The desired appointment start date is 11/02/2015.

- Masters or PhD in Pharmaceutical Sciences

- Degree: Master's Degree or Doctoral Degree.

-

Discipline(s):

- Life Health and Medical Sciences (1 )

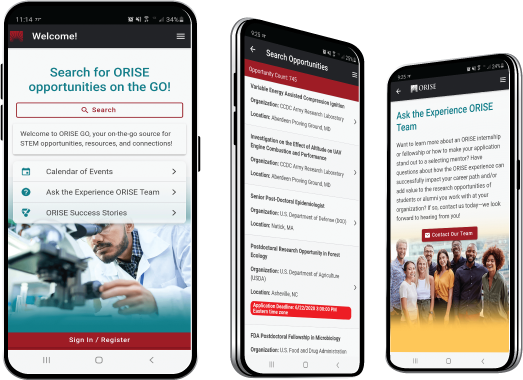

ORISE GO

ORISE GO

The ORISE GO mobile app helps you stay engaged, connected and informed during your ORISE experience – from application, to offer, through your appointment and even as an ORISE alum!